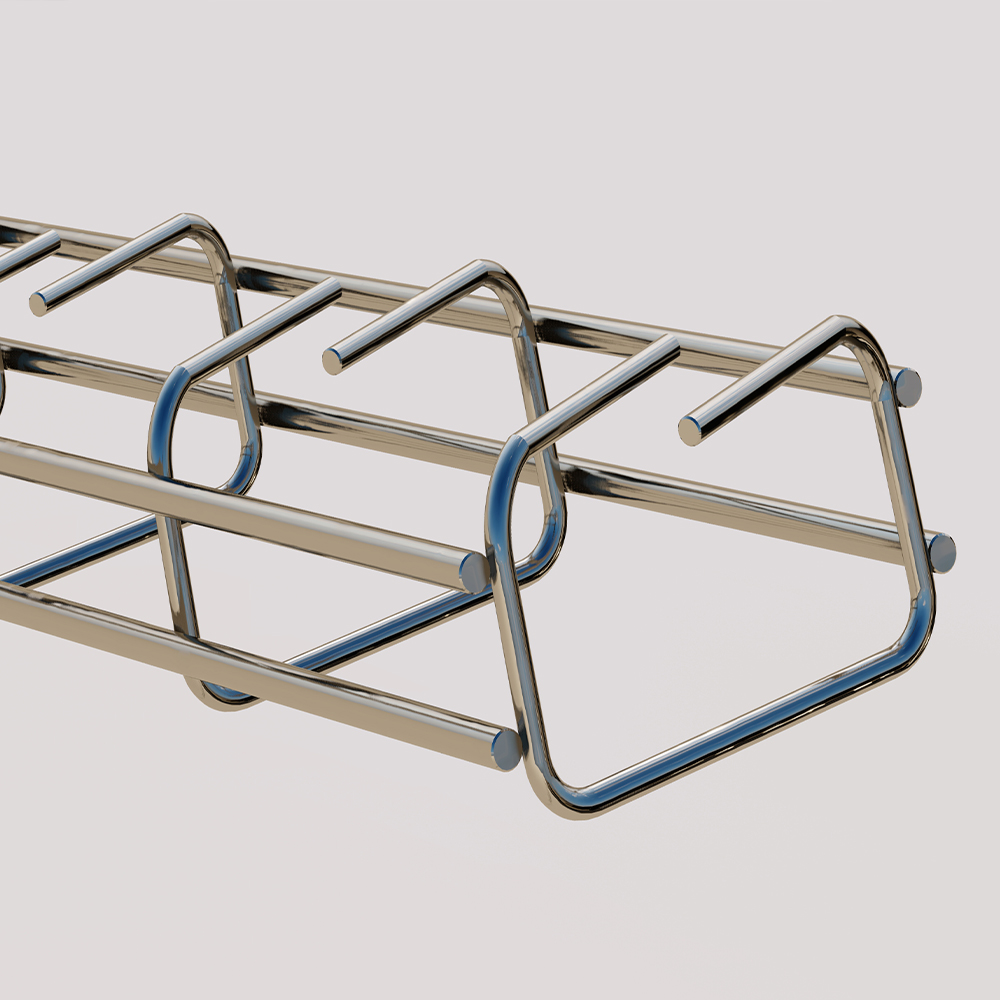

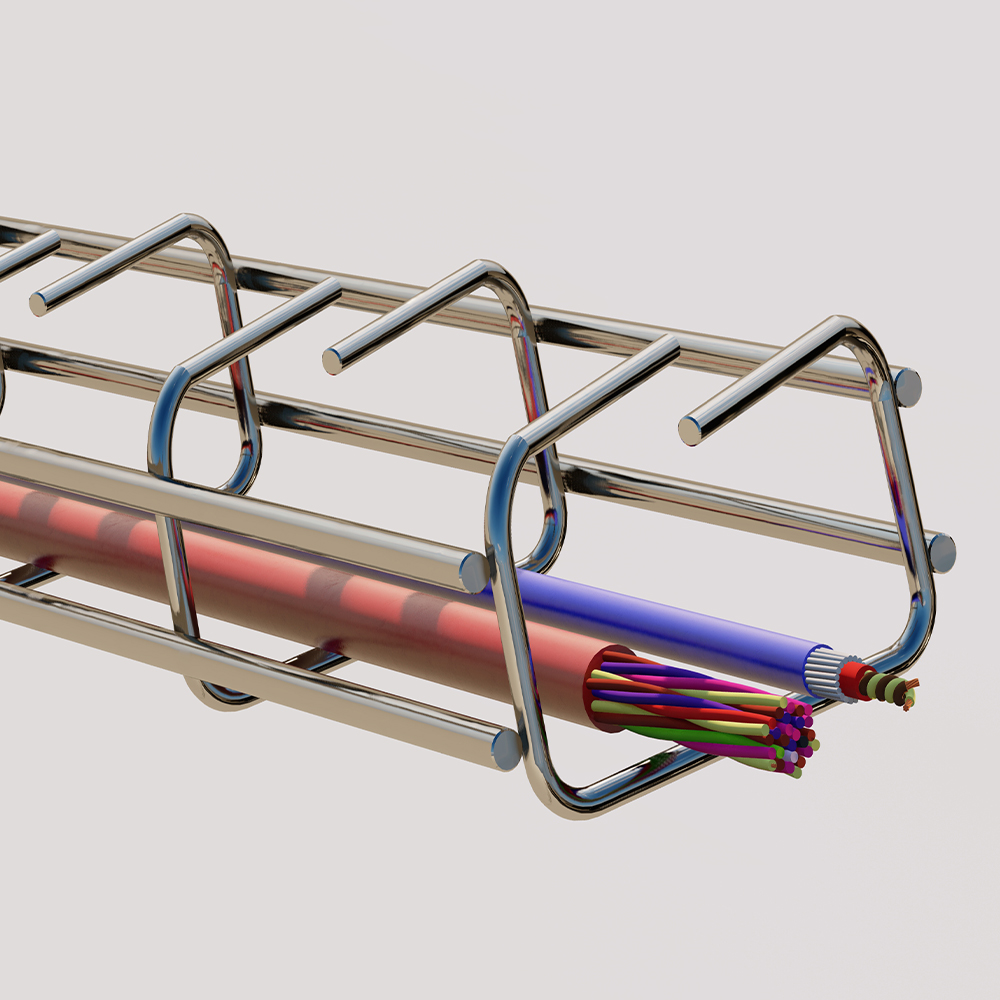

- CK Wiremesh Cable Tray concept based upon performance, safety and economy; three qualities which make CK Wiremesh Cable Tray system preferred by installers. CK Cable Tray Systems adapts to the most complex configurations, and its structure gives maximum strength for minimum weight. The ease of creating fittings, carried out on site, as well as the wide range of unique and universal accessories gives complete freedom in routing combined with exceptionally fast installation.

- The standard cable tray is a flexible solution in which the cables are easily accessible during cleaning and inspection. This cable tray is well-suited for the food and lumber industries and for IT environments and offices.

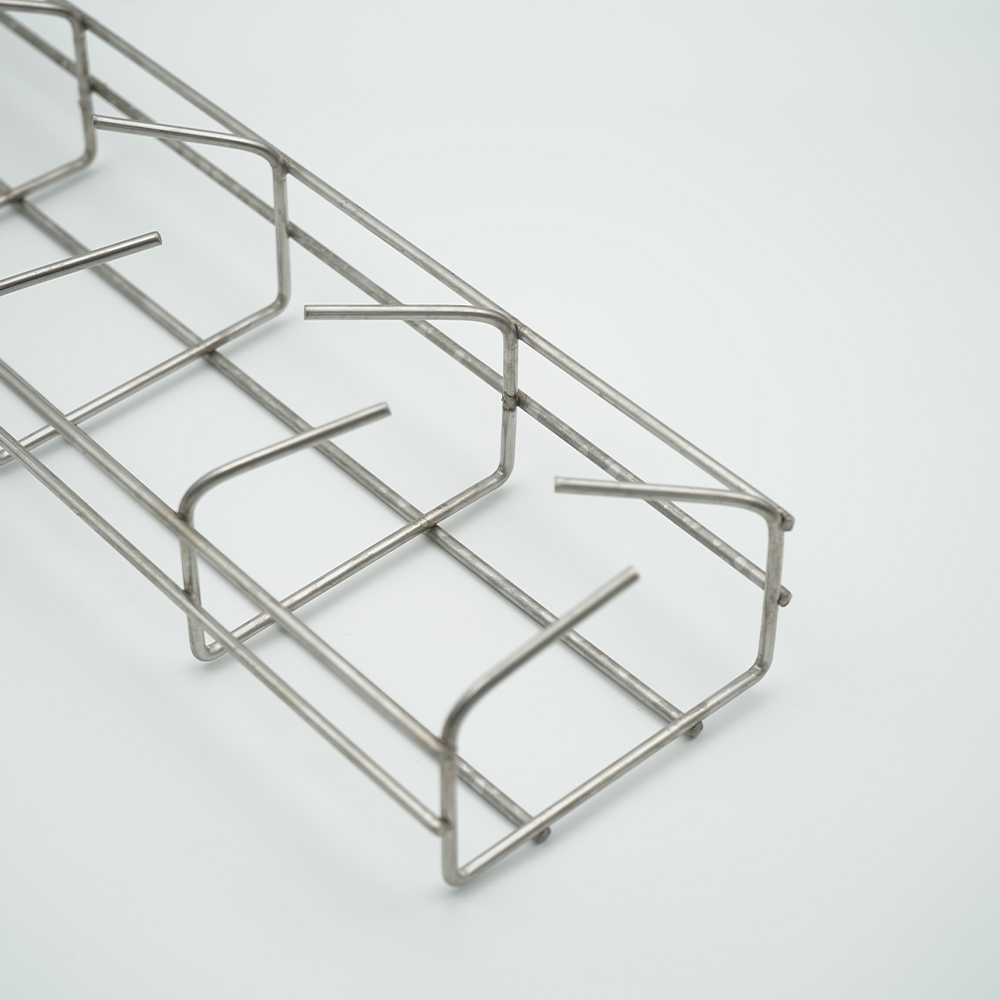

- The cable trays from CK Cable Trays are made of first-class stainless steel that prevents corrosion and ensures a good level of resistance.

- CK cable trays with a lock provides optimal and protected routing of cables, tubes and more. The trays are available in various sizes and they are made of solid, rounded materials.

- Cable trays of a special size can be produced according to customer requirements.

- Cable trays with a lock allow fast cable installation and exchange. At the same time, the cable trays are flexible and the cables are easily accessible during cleaning and inspection.

DESCRIPTION

The open design of the wire mesh cable tray provides good heat dissipation, flexible installation, and easy maintenance. It has a lightweight yet strong load rating capacity. Wire Mesh Cable Trays are widely used in communication equipment rooms, wind power stations, mechanical equipment, plant wiring, and other projects. Through years of effort, our Wire Mesh Cable Tray products have obtained ISO9001 quality system certification, and our products have obtained US UL, CUL, and European CE certifications.

TECHNICAL SPECIFICATIONS

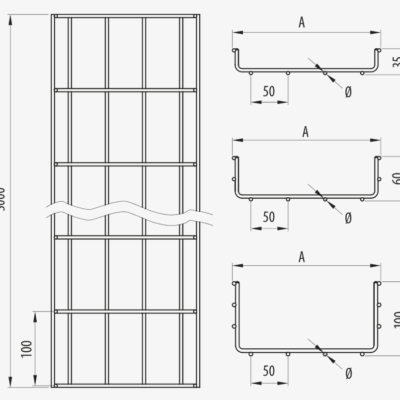

Wire diameter can be 3, 4, 5, or 6 , 8 mm.

Standart lenght (L) 3000 mm / on a request for specific dimension.

The coatings of the wires can be chosen as non coated (black) wire, electro-galvanized, pre galvanized (min. 40-60 gr/m2 Zn), hot dipped galvanized (min. 120 gr/m2 Zn), stainless steel, and electrostatic powder coated on galvanized or black wires.

The demand for our cable tray products has been increased over the years because cable trays are affordable, easy to use and light weighted comparing to the other cable management solutions.

Cable trays can carry and hold high weights. Also, they are well known as dust free and fireproof products.

| Product Name | SS 304 Wire Mesh Cable Tray |

| Mesh Size | 50mm×50mm,50mm×100mm, 200mm×100mm,300×200,ETC |

| Length | 3m or According to Requirements |

| Width | 50-1000mm, Size Can be Customized |

| Side Rail Height | 25-200mm, Size Can be Customized |

| Wire Diameter | 3.0-6.0mm, Size Can be Customized |

| Material | EG: Electro – Galvansed (8-12 mcron) EN ISO 2081 HDG-Steel, hot-dp galv. to TS-EN ISO 1461:2011 (HDG) SS – Stanless steel AISI 304L and ( aısı 201 aısı 204 ,aısı 316L (SS) ) EP- powder coating in a full range of colours (RAL) |

| Application | Construction, Energy, Electricity, Plant |

| Color | Silvery |

| MOQ | 1 m |

| Surface Treatment | Polished or not |

| Packing | Plastic Film Packaging, Carton Package, Woven Bag Package, Wooden Pallets. |

| Place of Origin | İzmir/TURKEY |

ADVANTAGES

Inexpensive

Light Weight

Dust Free / Easy to clean

Easy to Replace

Fireproof

Easy to Install

Cable Separation

Easy to change or replace the cables

Showcase

| Protection System | Flange | Width | kg/u | u |

| EG | 60 | 60 | 0.772 | 18 |

| EG | 60 | 100 | 0.811 | 24 |

| EG | 60 | 150 | 0.867 | 24 |

| EG | 60 | 200 | 1.110 | 18 |

| EG | 60 | 300 | 1.710 | 12 |

| EG | 60 | 400 | 2.070 | 6 |

| EG | 60 | 450 | 2.130 | 6 |

| EG | 60 | 500 | 2.450 | 6 |

| EG | 60 | 600 | 2.810 | 6 |

| EG | 100 | 100 | 1.090 | 12 |

| EG | 100 | 150 | 1.150 | 6 |

| EG | 100 | 200 | 1.380 | 6 |

| EG | 100 | 300 | 2.050 | 6 |

| EG | 100 | 400 | 2.410 | 6 |

| EG | 100 | 450 | 2.480 | 6 |

| EG | 100 | 500 | 2.780 | 6 |

| EG | 100 | 600 | 3.140 | 6 |

| Protection System | Flange | Width | kg/u | u |

| HDG | 60 | 60 | 0.772 | 18 |

| HDG | 60 | 100 | 0.811 | 24 |

| HDG | 60 | 150 | 0.867 | 24 |

| HDG | 60 | 200 | 1.110 | 18 |

| HDG | 60 | 300 | 1.710 | 12 |

| HDG | 60 | 400 | 2.070 | 6 |

| HDG | 60 | 450 | 2.130 | 6 |

| HDG | 60 | 500 | 2.450 | 6 |

| HDG | 60 | 600 | 2.810 | 6 |

| HDG | 100 | 100 | 1.090 | 12 |

| HDG | 100 | 150 | 1.150 | 6 |

| HDG | 100 | 200 | 1.380 | 6 |

| HDG | 100 | 300 | 2.050 | 6 |

| HDG | 100 | 400 | 2.410 | 6 |

| HDG | 100 | 450 | 2.480 | 6 |

| HDG | 100 | 500 | 2.780 | 6 |

| HDG | 100 | 600 | 3.140 | 6 |

| Protection System | Flange | Width | kg/u | u |

| SS304 | 60 | 60 | 0.772 | 18 |

| SS304 | 60 | 100 | 0.811 | 24 |

| SS304 | 60 | 150 | 0.867 | 24 |

| SS304 | 60 | 200 | 1.110 | 18 |

| SS304 | 60 | 300 | 1.710 | 12 |

| SS304 | 60 | 400 | 2.070 | 6 |

| SS304 | 60 | 450 | 2.130 | 6 |

| SS304 | 60 | 500 | 2.450 | 6 |

| SS304 | 60 | 600 | 2.810 | 6 |

| SS304 | 100 | 100 | 1.090 | 12 |

| SS304 | 100 | 150 | 1.150 | 6 |

| SS304 | 100 | 200 | 1.380 | 6 |

| SS304 | 100 | 300 | 2.050 | 6 |

| SS304 | 100 | 400 | 2.410 | 6 |

| SS304 | 100 | 450 | 2.480 | 6 |

| SS304 | 100 | 500 | 2.780 | 6 |

| SS304 | 100 | 600 | 2.810 | 6 |

| Protection System | Flange | Width | kg/u | u |

| SS316 | 60 | 60 | 0.772 | 18 |

| SS316 | 60 | 100 | 0.811 | 24 |

| SS316 | 60 | 150 | 0.867 | 24 |

| SS316 | 60 | 200 | 1.110 | 18 |

| SS316 | 60 | 300 | 1.710 | 12 |

| SS316 | 60 | 400 | 2.070 | 6 |

| SS316 | 60 | 450 | 2.130 | 6 |

| SS316 | 60 | 500 | 2.450 | 6 |

| SS316 | 60 | 600 | 2.810 | 6 |

| SS316 | 100 | 100 | 1.090 | 12 |

| SS316 | 100 | 150 | 1.150 | 6 |

| SS316 | 100 | 200 | 1.380 | 6 |

| SS316 | 100 | 300 | 2.050 | 6 |

| SS316 | 100 | 400 | 2.410 | 6 |

| SS316 | 100 | 450 | 2.480 | 6 |

| SS316 | 100 | 500 | 2.780 | 6 |

| SS316 | 100 | 600 | 2.810 | 6 |

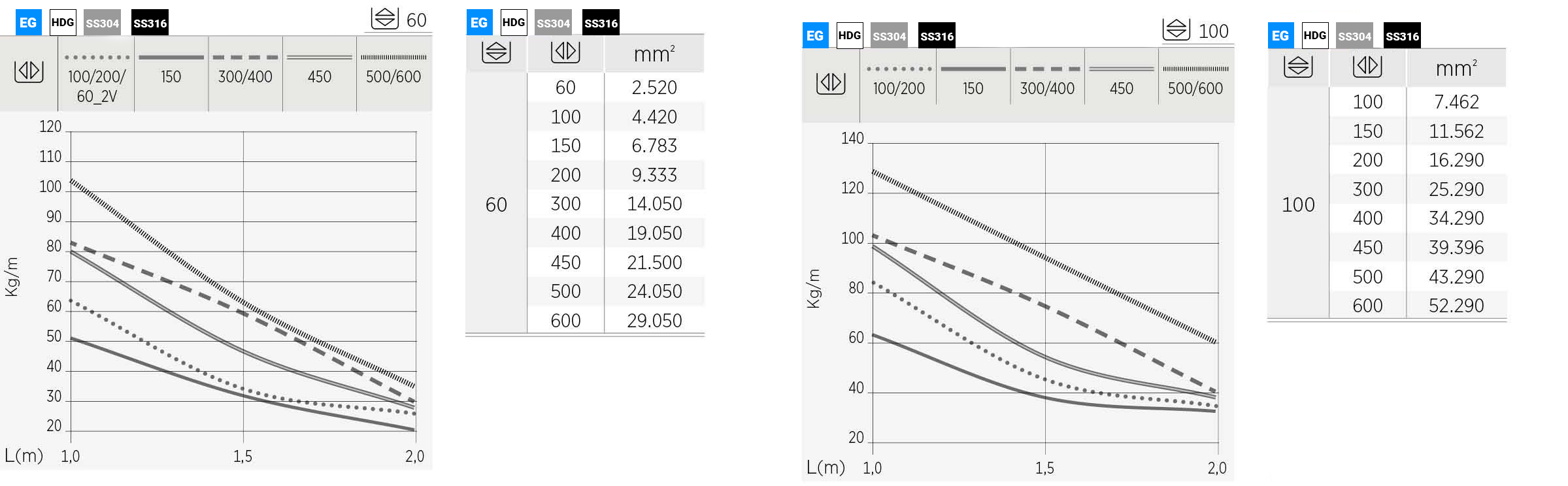

LOAD DIAGRAMS